Custom Die Cutting

Custom Die Cutting

Custom Die Cutting

Custom die-cutting is the most popular service that we offer. We custom die cut materials as a stand-alone service and as part of our custom manufacturing solutions. If you need custom die cutting services, contact us by filling out our quote-request form and emailing it to sales@customconverting.com, fill out our online contact form, or just calling us at (760) 724-0664.

Die-cutting is the process of cutting components quickly and efficiently with a consistent cut every time. Die cutting machines are used to speed up the manufacturing process and withstand the constant pressures of a heavy workload. When you need millions of parts, whether those parts are medical testing components, face shields, or adhesive strips, Custom Converting will get the job done.

Die cut parts are a component of most manufactured items. We can make your product from the ground up or make one piece of your finished product. Why add expensive equipment with a large footprint to your facility? Custom Converting will do the die-cutting for you. We custom manufacture your parts to your specifications, working closely with you to provide the best service in the industry.

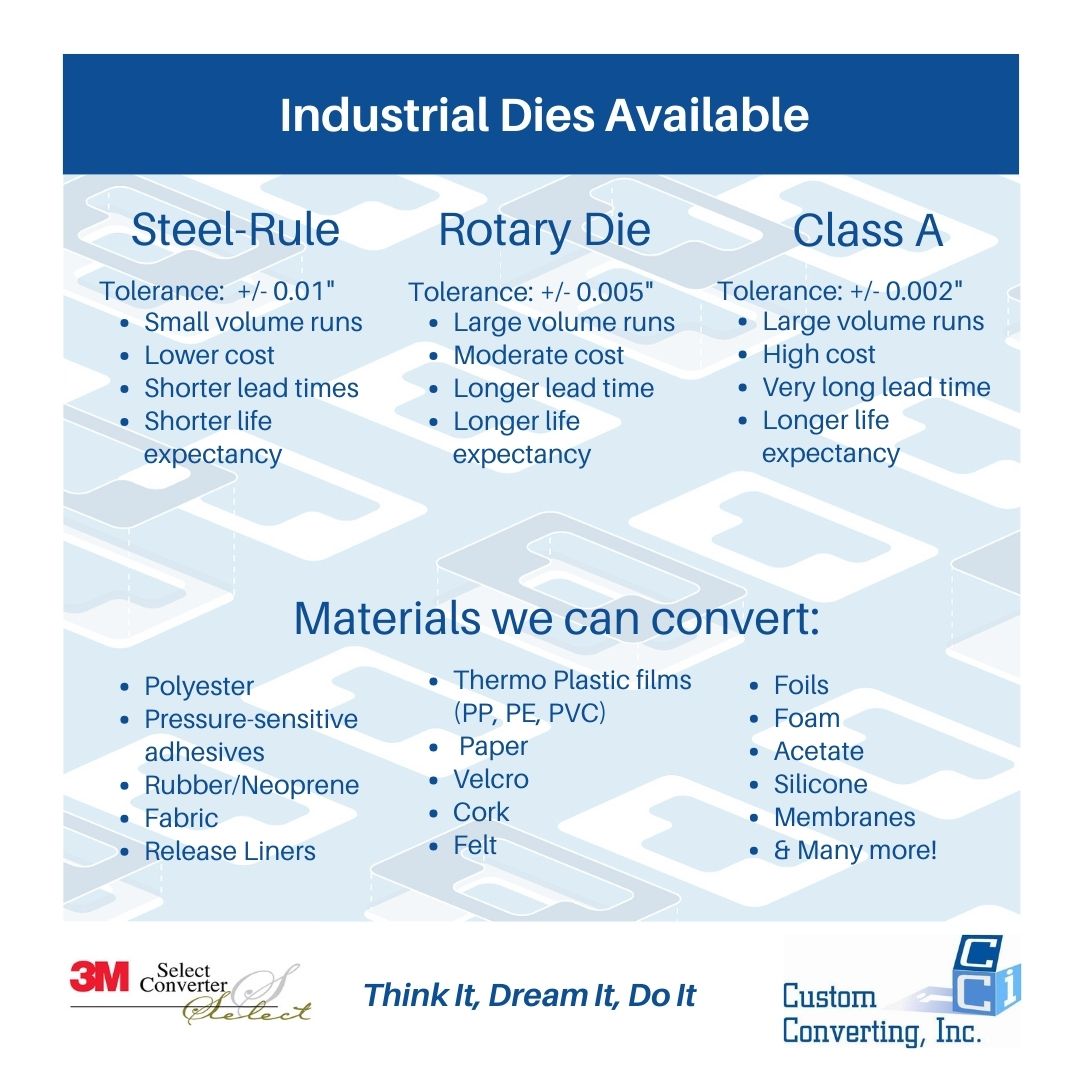

We die cut a wide variety of materials and have the ability to obtain custom dies in nearly any shape or size that you need. This service can be used for industries like medical diagnostic, aerospace, biotech, electronics, and fashion, as well as many others.

If your product requires a custom steel rule die, we’ll get a die made and start die cutting for you in short order.

Need more accuracy than steel-rule dies provide? We offer precision rotary dies as well as Class A custom dies.

Whatever the shape, size or tolerance of your final product, we can have a die made to accommodate your needs.

See our capabilities page for more details or contact us directly for more details.

Materials for Custom Die Cutting

Materials for Custom Die Cutting

Custom die cutting can be performed on a wide variety of materials. Please contact us if the material you’d like to use doesn’t appear above.

If your material requires special handling and/or storage, such as a temperature and/or humidity-controlled environment, please let us know. These services are available in our 20,000+ sq. ft. facility.

Would you like to have a 3M specialty product die cut for your project? Custom Converting is a 3M Select Converter, and we have access to their full catalog of materials.

Remember – “Quality is in our DNA!”

Custom Die Cutting Terms:

Custom Die Cutting Terms:

Through Cutting:

Fully die-cut parts are parts which have been cut through all the layers of the product (through cut). These include items like face-shields and diagnostic testing sticks. As a custom manufacturer, we’re prepared to work with nearly any material to create an astounding variety of products.

Kiss cutting:

Kiss cutting can be a two-level die-cutting operation that cuts the shape through all the layers of your product and leaves it on the liner. Typical kiss-cut parts might look like topical patches or labels which can be put onto rolls or reels for easy removal from the silicone liner.

Rotary Die Cutting:

Rotary die cutting is a special kind of die cutting that uses a cylindrical die to cut shapes out of material. The die cutting process is incredibly efficient because it cuts out many identical shapes as it rotates.

Score Cutting:

Score cutting is another two-level die cutting operation that allows us to produce crack and peel on the silicone liner to help remove the liner more easily.

What are the Steps in Custom Die Cutting?

What are the Steps in Custom Die Cutting?

First, we work from your specifications to obtain exactly the die that will work best for your project. We put our decades of experience in converting and custom manufacturing to work for you, manufacturing to your specifications every time.

Meanwhile, we obtain the materials to be used in your project, whether you’d like us to order those materials from 3M or one of our other vendors. Or we can die cut materials that you supply.

Next, we test the die and materials to make certain that your parts will be manufactured within the tolerances you have set.

Finally, we cut the materials you’ve specified, in the quantity you’ve requested.

Quality is in our DNA, and you’ll be thrilled with the results of your die cutting, whether you’re ordering one component for your own manufacturing process or you’re having us deliver a customer-ready final product.

Custom Die Types:

Custom Die Types:

At Custom Converting, we recommend dies to our customers based on the application requested, volume and accuracy tolerances required.

- Steel rule dies offer a die-cutting surface up to 11”x19”, with a tolerance of +/- .010”. The advantages of steel rule die cutting include accuracy, simplicity, and low tooling costs.

- Precision rotary dies have a tolerance up to +/- .005” and up to a 16” web width. The advantages include speed and uniformity.

- Class A dies are our most accurate dies, offering accuracy up to +/- .002” with camera registration, and can utilize up to a 19” web width.

Contact Us Today for a Free Quote:

Contact Us Today for a Free Quote:

We’ve provided die cut electronics, components for the aerospace industry, provided biomedical die cutting services, and worked with the fashion industry. We perform 3M adhesive tape die cutting services, and offer high precision die cutting. Whatever your industry, Custom Converting is ready to work with you.

Complete the form on our website or the detailed request for quotation available here and email it to sales@customconverting.com. You can also call us at (760) 724-0664.